Technology and design

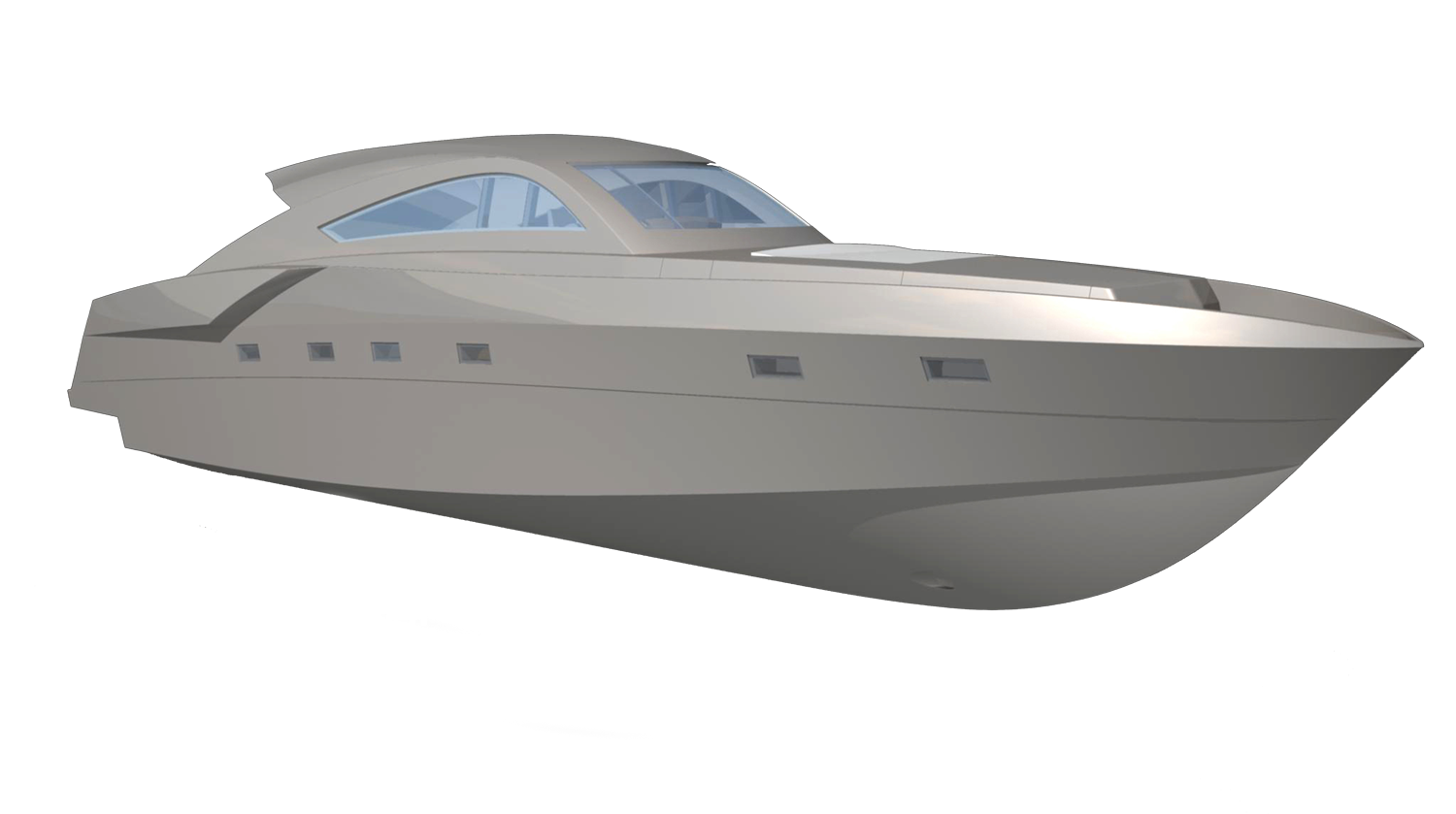

The Gari 70 has been designed with the needs of owners who like to sail in all sea conditions in mind; the water line study, developed through numerous ship tank tests, is designed for sailing comfort with formed seas at maximum speed, ensuring absolute top performance.

With Gari 70 you no longer have to choose

The driver’s station is mounted on a mechanism, patented worldwide, that allows the entire helm station (sofa, dashboard and rudder) to rise about 80 cm. above the salon floor level; this will allow the owner to drive the boat either in coupe condition, i.e., with the driver completely inside the boat, or in convertible condition, i.e., with the boat driver partially outside the hard-top.

Italian's style

The Gari 70 is certainly the most innovative and technological pleasure motor boat produced in Italy.